Model-Based Risk Engineering

Redefined

The Maintenance Aware Design Ecosystem or MADE is a model-based industry standard for RAMS (Reliability, Availability, Maintainability, Safety). The MADE platform is Reliability Software designed to transform how engineers identify, evaluate, and mitigate technical risk in complex mission-critical systems. It serves as a digital backbone for reliability & safety engineering teams developing systems across aerospace, defense, transportation, energy and any sector that designs, builds and operates complex-mission critical systems.

Unlock Product Value with MB-RAMS

Smarter Decisions, Higher Quality Systems

Built on Digital Engineering principles you’d expect from industry leading reliability software, MADE digitizes domain expertise and automates RAMS workflows through the creation of Digital RAMS Twins. These twins connect design intent with operational performance, dynamically representing system reliability and risk via indentured system modeling, dependency mapping, and failure simulation. The result: informed, traceable decisions that add up to safer, more resilient systems.

MADE as an Integrated RAMS Toolset

MADE comprises four core, interlinked modules, making it the first RAMS tool in market that integrates data (utilizing a Standardized Taxonomy) within each RAMS discipline. MADE consists of the following modules:

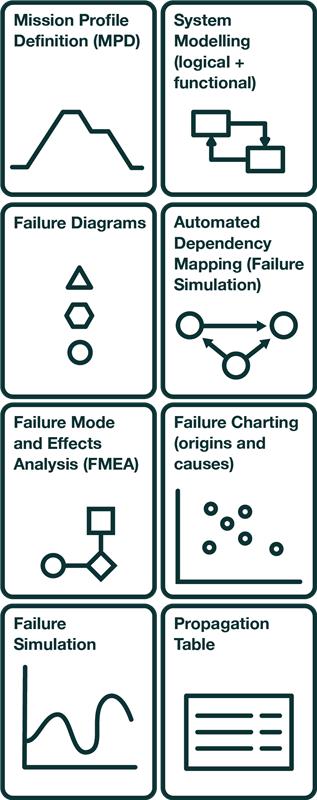

Digital RAMS Twin Creation

Establishes the system architecture and failure logic.

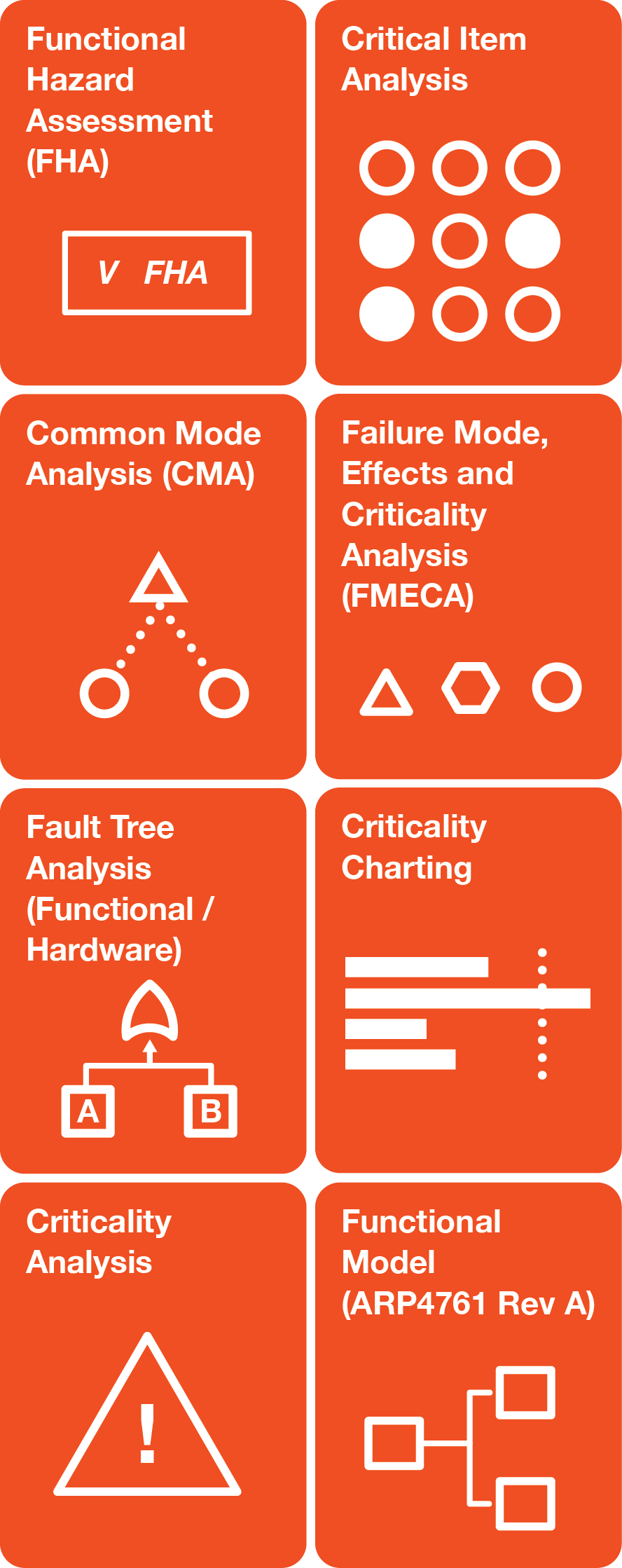

Safety, Risk Assessment

Enables simulation-based safety, reliability, and cost trade-off studies across design alternatives.

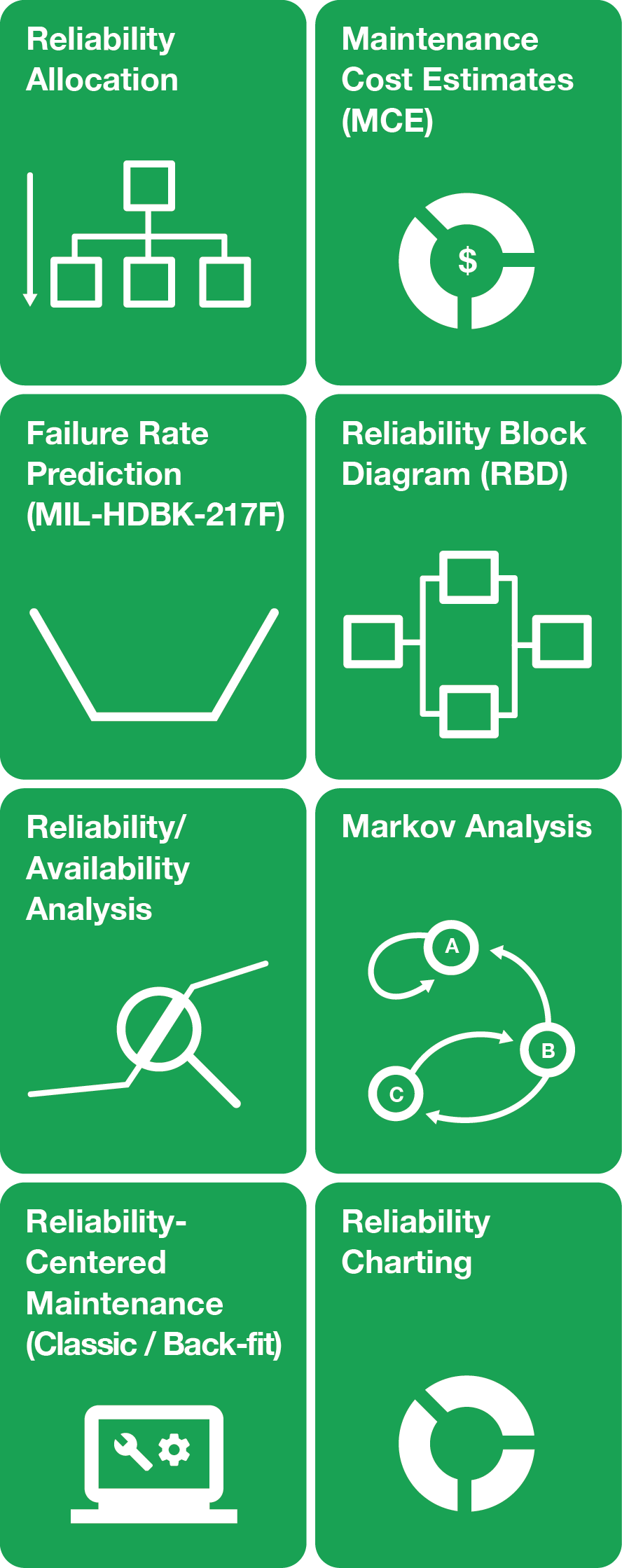

Reliability, Availability, Maintainability

RAM Module helps you predict and prevent system failures, optimize redundancy, and set reliability targets that align with performance and mission goals.

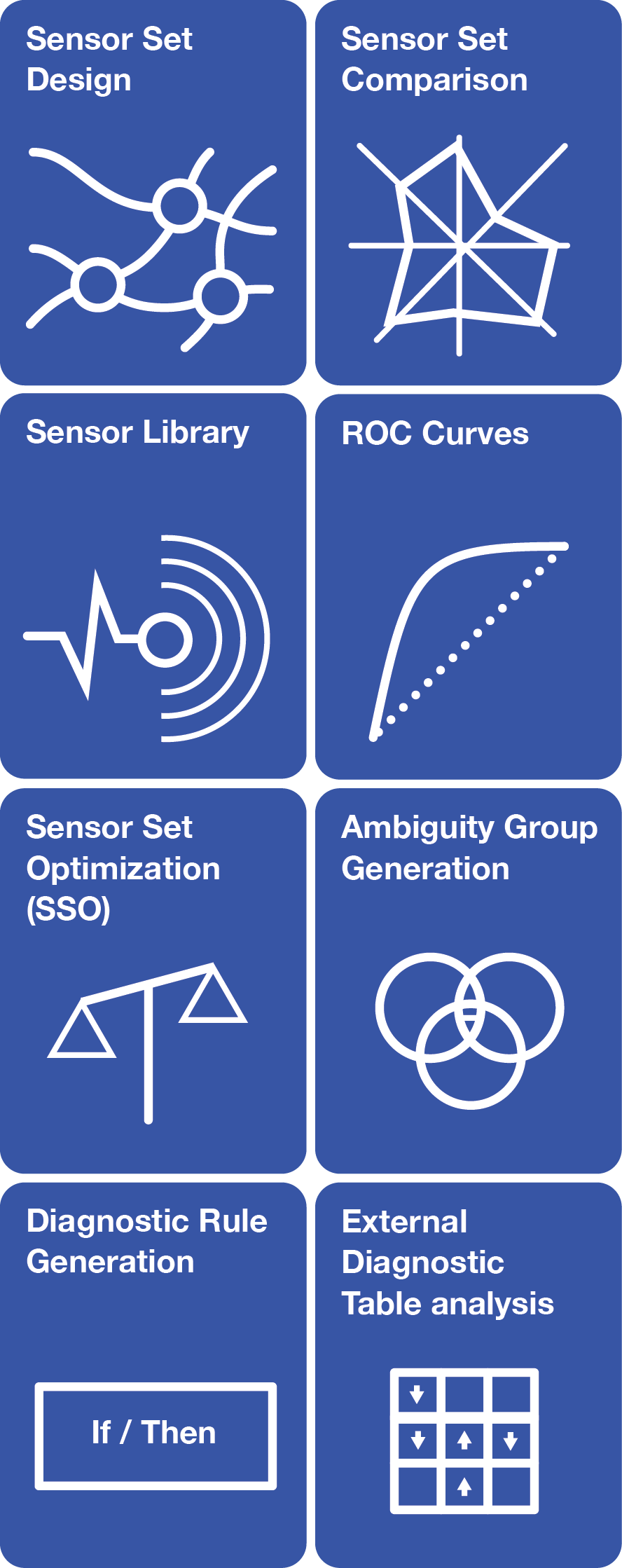

Prognostic Health Management

The PHM (Prognostics and Health Management) Module in the MADE platform verifies diagnostic designs and supports PHM trade studies through model-based analysis.

Unlock the Power of Model-based RAMS

Find Out How – Download the MADE Brochure

Click the image to download and see how MADE transforms your RAMS strategy into a competitive advantage.

MADE is part of an Ecosystem

From simulation to in-service insights, MADE connects seamlessly into the future of asset management. The PHMT Ecosystem extends your Digital Risk Twin (DRT) beyond design into operations/sustainment with the MODE platform through the Digital RAMS Backbone (DRB).

Unlocking System Excellence

The Benefits of a Model-Based RAMS Approach

Early Risk Identification

Simulate and resolve potential hazards before build phase.

Integrated Digital Twin

Continuously and cohesively analyze safety, reliability, and maintenance in real time.

Enhanced Collaboration

Accessibility, shareability, and standardized data models promote cross-disciplinary alignment and distributed participation.

Accelerated Certification

Automate compliance workflows and generate audit-ready artifacts

Lifecycle Cost Reduction

Optimize support strategies and reduce unplanned downtime.

Data Reusability

Capture domain knowledge for reuse across platforms and programs.

Future-State Readiness

As every industry advances rapidly towards embracing AI and other leading technology your RAMS design data can be more effectively utilized if it is digitized using a consistent taxonomy.

Start Your MADE Software Journey Today

Let’s explore how the MADE Realibility Software can transform your engineering processes

Whether you have a specific challenge in mind or just want to learn more, we’re here to help. Fill out the form below and one of our experts will get back to you shortly with insights tailored to your needs.

Explore What MADE Can Do for Your Organization

Select the Features You Want to Learn More About

Discover the powerful capabilities of MADE by exploring the table below. Simply check the boxes next to the features/functionality you’re interested in and hit submit — we’ll make sure you get more information tailored to your needs.

Request Your Selected Capability Overview Demonstration

Enter your details below and we’ll organise a custom demonstration based on these selections.

Related Whitepapers

MADE: Development of an Aerospace PHM Software Tool

The Maintenance Aware Design environment (MADE) was conceived to provide a suite of software tools that could be used to design, assess and optimise Prognostics and Health Management systems for use in a wide variety of high risk industries where safety and reliability are critical, including mining, offshore and aerospace applications. MADE is currently being developed for application to aerospace systems and…

Download the paper

language of FMEA: effective use and reuse of FMEA data

Practical uses of Failure Modes and Effects Analysis (FMEA) range from the identification of potential design defects and safety hazards, to maintenance planning, diagnostics and Prognostics and Health Management (PHM). According to the broadly accepted standard for FMEA, MIL-STD-1629A, a successful FMEA is one that conducted in a timely manner, so that the results can be used to…

Download the paper