Condition Aware by Design

Anticipate Failures. Optimize Availability. Assure Operational Confidence.

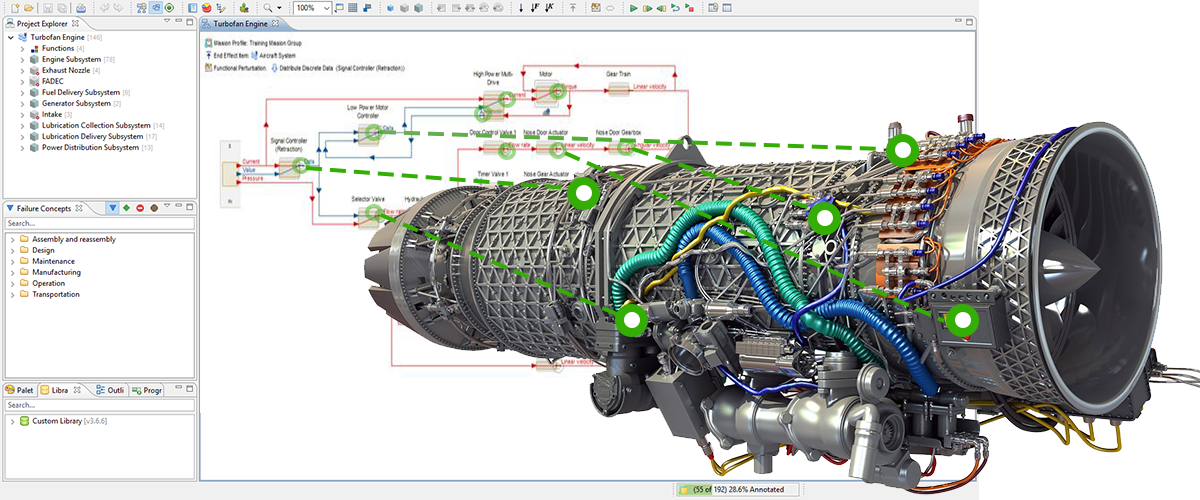

Eliminate reactive maintenance by modeling system-level failure responses and identifying condition monitoring opportunities. Support early, model-based validation of diagnostics and prognostics, ensuring health monitoring strategies are both robust and relevant. Run trade studies on sensor sets, fault logic, and failure coverage, reducing false alarms, improving detection, and cutting lifecycle costs. The PHM Module ensures your system is built to last.

MADE PHM Module

Get Proactive for Smarter Sustainment

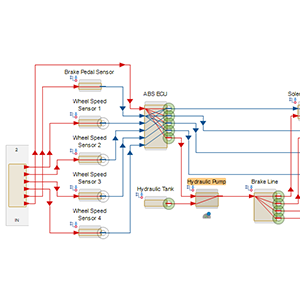

The MADE Prognostics & Health Management (PHM) Module enables engineers to anticipate and address system failures before they impact operations. By modeling failure behavior, simulating diagnostic performance, and validating condition monitoring strategies early in the design process, PHM transforms reactive maintenance into a proactive, cost-effective capability.

Whether you’re designing for certification or operational resilience, the PHM Module equips teams with the tools to engineer smarter health management solutions, from selecting the right sensors to verifying failure detectability and reducing maintenance uncertainty.

PHM Module High-level Features

Anticipate, Adapt, and Act

Proactive System Health & Performance Management

The PHM Module integrates diagnostic intelligence directly into system design. It supports early identification of latent risk factors and enables data-driven sensor placement using system dependencies. Streamline sensor selection and drastically improve fault isolation and health assessment through automated design. Together, these capabilities help organizations design more maintainable and observable systems from the outset.

Why MADE-PHM?:

Eliminate Reactive Maintenance – Design-in intelligence to predict and manage failures before they occurEarly Diagnostic Validation – Simulate and assess detection and isolation logic during design—not after deploymentOptimize Sensor Strategies – Run trade studies to balance coverage, cost, and performanceReduce False Alarms & Missed Detections – Improve reliability and operator trust in diagnostic alertsSupport Certification Readiness – Generate auditable, model-based evidence for PHM performance and complianceCausation-based AI – Detailed failure syndromes assist in building a Causation-based AI approach to FDI.

Unlock the Power of Model-based PHM

Find Out How – Download the MADE-PHM Brochure

Click the image to download and see how MADE transforms your PHM strategy into a competitive advantage.

Stay Ahead of Failure

Predict. Diagnose. Sustain with Confidence.

The MADE PHM Module helps engineers shift from reactive maintenance to proactive system design. By simulating failure behavior and validating diagnostics early, it ensures robust, field-ready health monitoring solutions.

Key capabilities of this module include:

PHM Modeling Capabilities

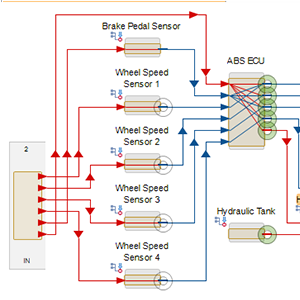

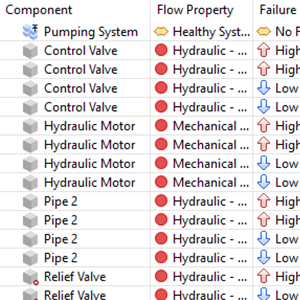

Identify the existing sensors of components / systems in the model

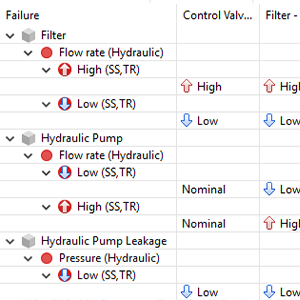

Inherent Diagnostic Capability Assessment

Determine the existing diagnostic coverage of failures based on an existing (Legacy) sensor set

Theoretical Diagnostic Capability Assessment

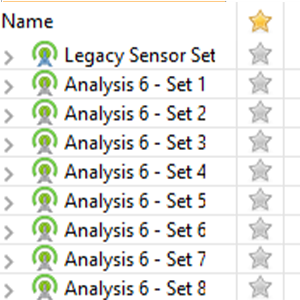

Automated sensor set design that uses AI to maximize failure detection and isolation (Design)

Sensor Ambiguity Groups

Autonomously identify failures that cannot be uniquely identified with a selected sensor set

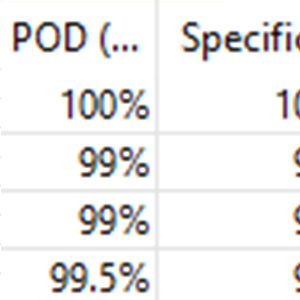

Sensor Design Trade Studies

Compare sensor sets based on metrics including cost, coverage, weight, etc.

Diagnostic Rules Generation

Auto-generate the sensor responses used to isolate specific failures

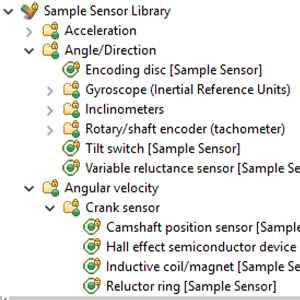

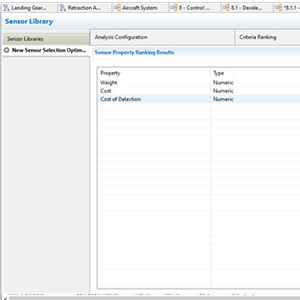

Sensor Libraries

Library of >900 sensor types, the details of specific sensors can be saved and reused for different projects

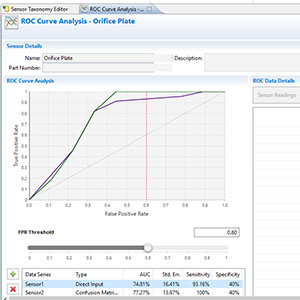

ROC Curves

Receiver Operating Characteristic (ROC) curves use sensor failure data to plot the relationship between True Positives and False Positives observed based on a sensor’s test threshold

Sensor Selection Optimization

Optimization algorithm to identify specific sensors based on user-defined metrics (physical dimensions, performance, reliability, etc.)

Start Your MADE Software Journey Today

Let’s explore how the MADE Realibility Software can transform your engineering processes

Whether you have a specific challenge in mind or just want to learn more, we’re here to help. Fill out the form below and one of our experts will get back to you shortly with insights tailored to your needs.

Related Whitepapers

MADE: Development of an Aerospace PHM Software Tool

The Maintenance Aware Design environment (MADE) was conceived to provide a suite of software tools that could be used to design, assess and optimise Prognostics and Health Management systems for use in a wide variety of high risk industries where safety and reliability are critical, including mining, offshore and aerospace applications. MADE is currently being developed for application to aerospace systems and…

Download the paper

language of FMEA: effective use and reuse of FMEA data

Practical uses of Failure Modes and Effects Analysis (FMEA) range from the identification of potential design defects and safety hazards, to maintenance planning, diagnostics and Prognostics and Health Management (PHM). According to the broadly accepted standard for FMEA, MIL-STD-1629A, a successful FMEA is one that conducted in a timely manner, so that the results can be used to…

Download the paper